Bringing excellence by originality and realizing dreams by high quality

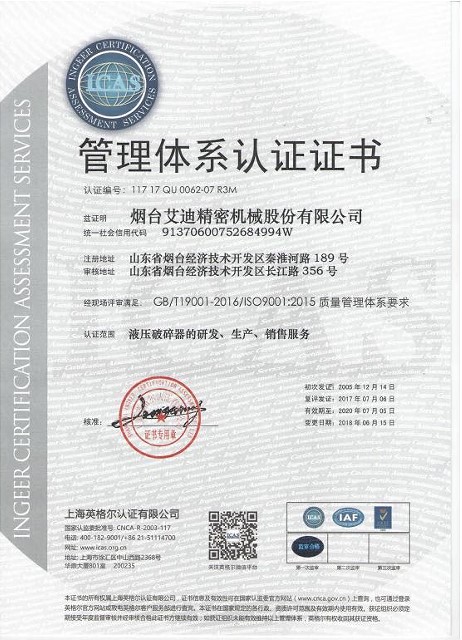

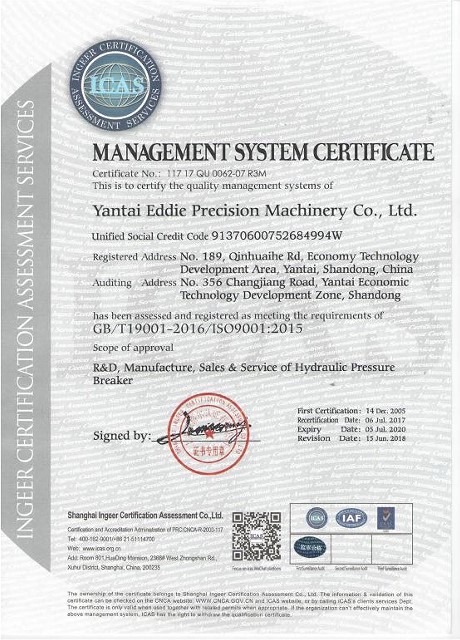

Yantai Eddie Precision Machinery Co., Ltd was founded in August of 2003 and listed on the main board of the Shanghai Stock Exchange in 2017( stock code : 603638 ), covers an area of 670000 ㎡.

2,800 staff allocated proportionately across the divisions handling hydraulic hammers, attachments, hydraulic parts, robots, machining tools, energy storage technologies and equipments, precision linear motion, etc.

After two decades of development, we have now made an international reputation as a precision Mechanical Technology Company, having sold our products to more than 90 countries and regions, establishing an excellent corporate image and international brand.

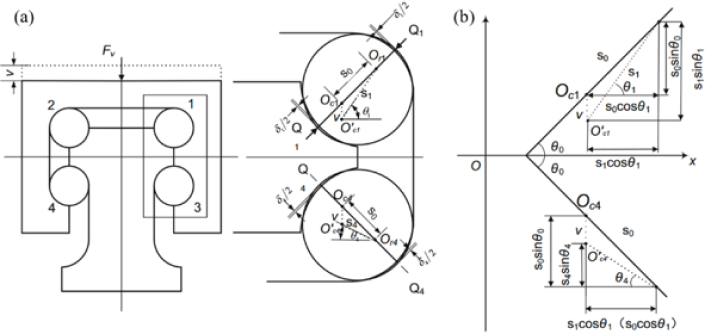

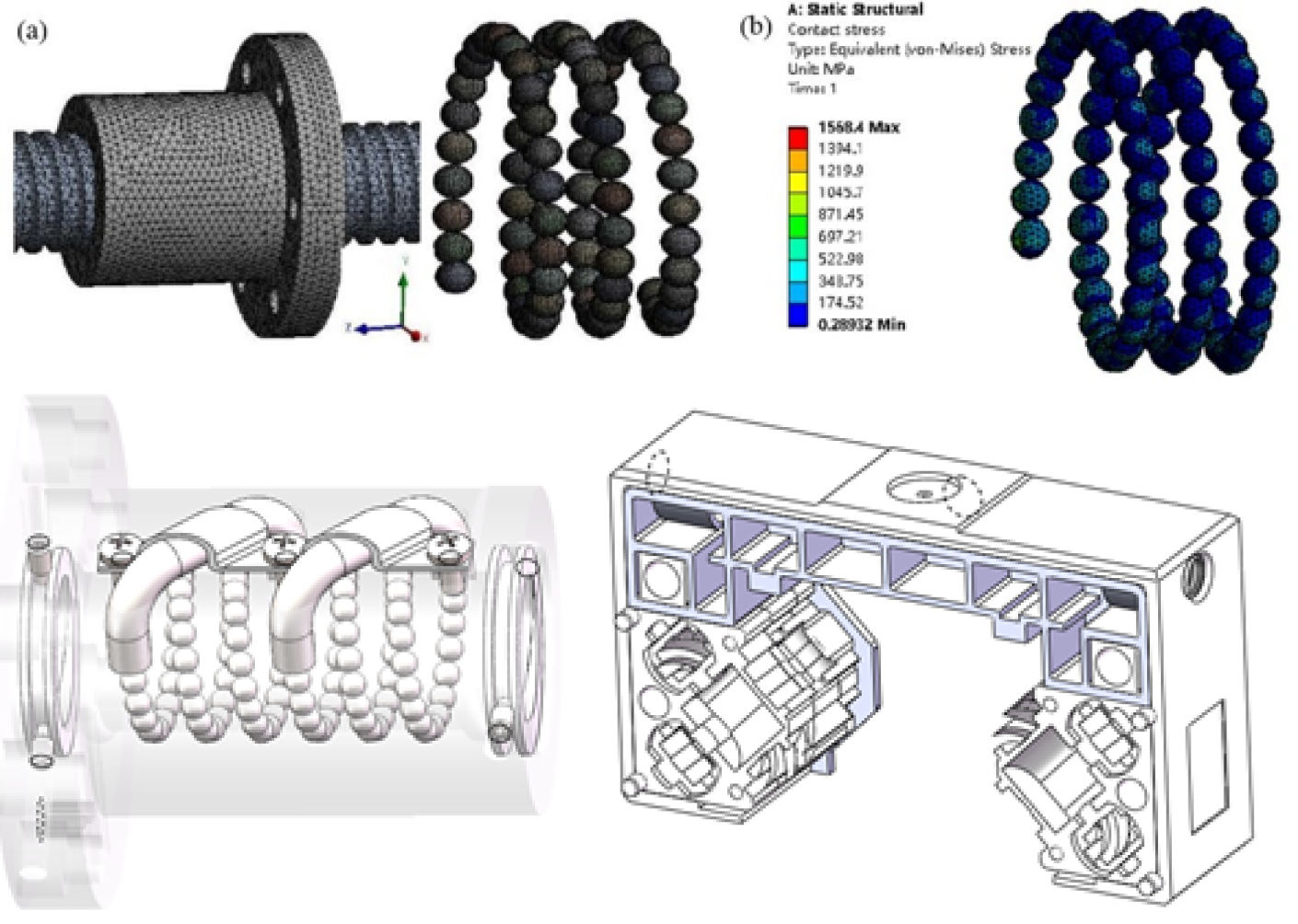

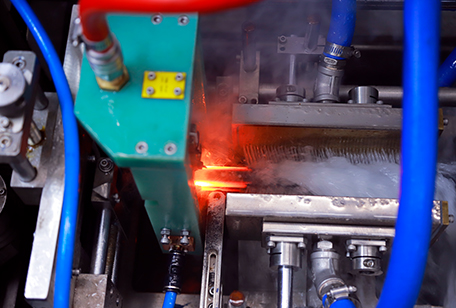

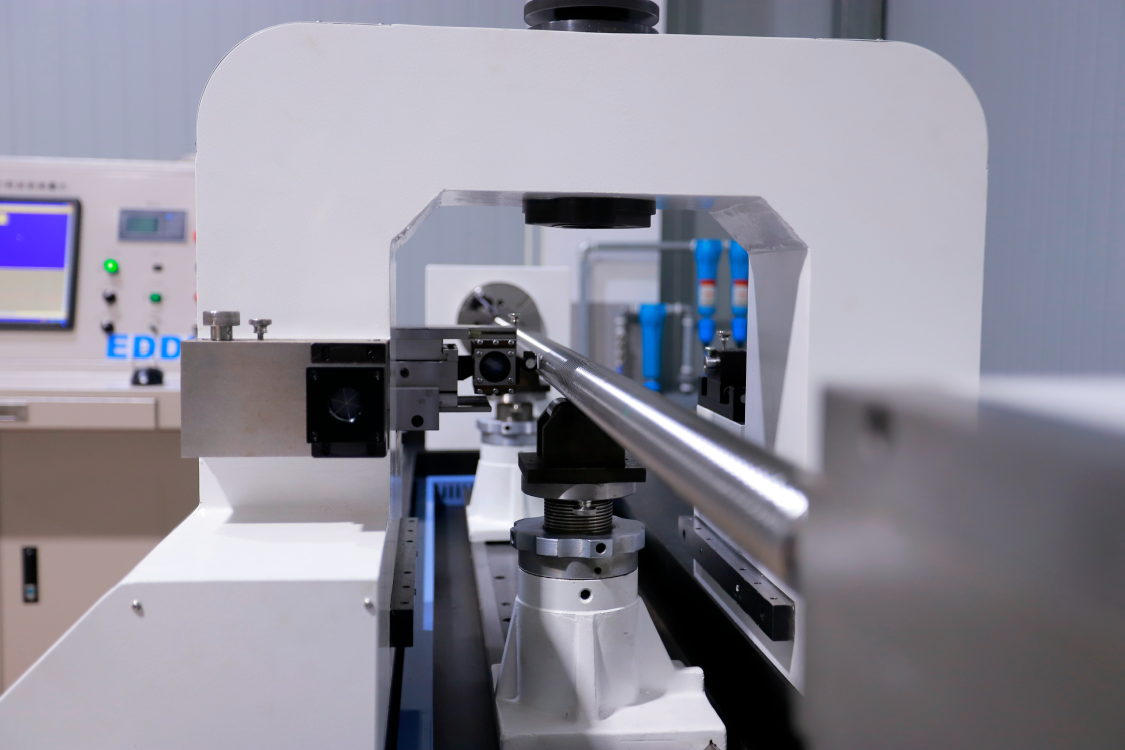

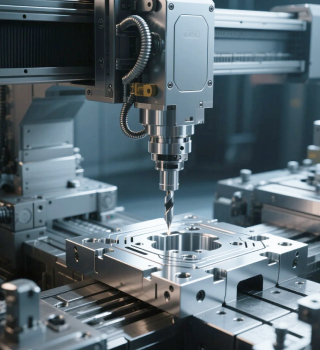

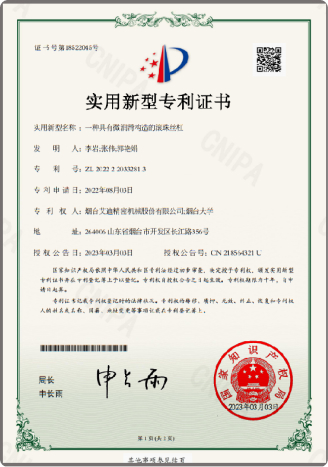

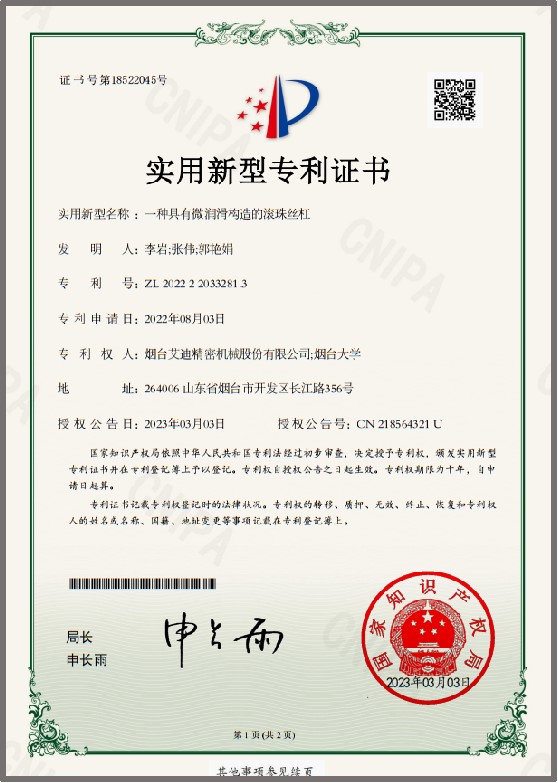

Established in 2021, EDDIE Linear Motion is a division directly under the management of Yantai EDDIE Precision Machinery Co., Ltd. We specialize in the R&D, manufacturing, and sale of ball screws, linear guide rails, electric cylinders, as well as other precision linear motion products. At the same time, we also supply the core parts of high-end equipment that are extensively used in CNC machine tools, semiconductors, automobiles, engineering machinery, aeronautics, and astronautics. We aim to become a world-class research, development, and manufacturing company of high-precision linear motion products.

160+

billion RMB(≈22 billion USD),Market value of parent company,September 2023.